Encyclopedia Dubuque

"Encyclopedia Dubuque is the online authority for all things Dubuque, written by the people who know the city best.”

Marshall Cohen—researcher and producer, CNN

Affiliated with the Local History Network of the State Historical Society of Iowa, and the Iowa Museum Association.

TAP HANDLES: Difference between revisions

No edit summary |

No edit summary |

||

| Line 3: | Line 3: | ||

The original beer tap was a simple device to control the flow of beer from a cask. Similar taps are still used today - simple open/close valves. Casks have a hole at the lowest point at one end when they are laid on their side. The tap is twisted or pressed to open the valve, gravity takes over and the beer flows. | The original beer tap was a simple device to control the flow of beer from a cask. Similar taps are still used today - simple open/close valves. Casks have a hole at the lowest point at one end when they are laid on their side. The tap is twisted or pressed to open the valve, gravity takes over and the beer flows. | ||

[[Image:dubuquestartap.png|left|thumb|250px|Many bars are set up differently with the casks under the bar or in a cellar. In these cases, with the cask being below where it is dispensed, gravity cannot drive the beer. A beer engine, a simple pump, does the work. Long beer tap handles are attached to the beer engine. When they are pulled, the pump pushes the beer out of the dispenser and into the glass. When the handles are pushed back the engine draws more beer - often about half a pint - through a tube attached to the cask. | [[Image:dubuquestartap.png|left|thumb|250px|]]Many bars are set up differently with the casks under the bar or in a cellar. In these cases, with the cask being below where it is dispensed, gravity cannot drive the beer. A beer engine, a simple pump, does the work. Long beer tap handles are attached to the beer engine. When they are pulled, the pump pushes the beer out of the dispenser and into the glass. When the handles are pushed back the engine draws more beer - often about half a pint - through a tube attached to the cask. | ||

The most common modern beer tap is the pressurized tap. These are supplied with beer from a keg and run by applied pressurized gas to the keg forcing the beer out. When the beer tap handles on this system are pulled they open a valve. Because the beer is under pressure in the keg it is pushed out of the dispenser. | The most common modern beer tap is the pressurized tap. These are supplied with beer from a keg and run by applied pressurized gas to the keg forcing the beer out. When the beer tap handles on this system are pulled they open a valve. Because the beer is under pressure in the keg it is pushed out of the dispenser. | ||

Revision as of 20:54, 20 January 2010

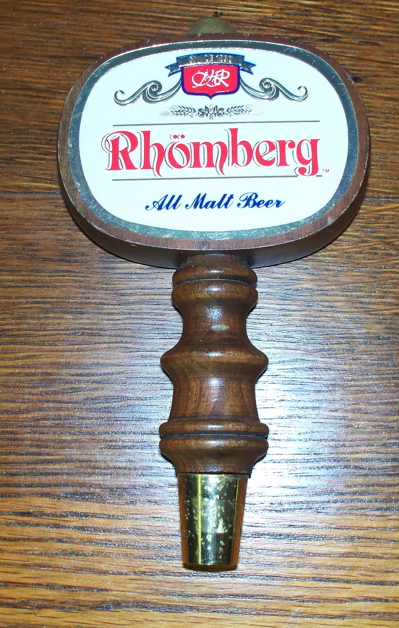

TAP HANDLES. From simple open/close valves to ornate sculptures of purpose behind the bar to garish points of advertisement, beer taps and the handles that run them are important artifacts of the beer making industry.

The original beer tap was a simple device to control the flow of beer from a cask. Similar taps are still used today - simple open/close valves. Casks have a hole at the lowest point at one end when they are laid on their side. The tap is twisted or pressed to open the valve, gravity takes over and the beer flows.

Many bars are set up differently with the casks under the bar or in a cellar. In these cases, with the cask being below where it is dispensed, gravity cannot drive the beer. A beer engine, a simple pump, does the work. Long beer tap handles are attached to the beer engine. When they are pulled, the pump pushes the beer out of the dispenser and into the glass. When the handles are pushed back the engine draws more beer - often about half a pint - through a tube attached to the cask.

The most common modern beer tap is the pressurized tap. These are supplied with beer from a keg and run by applied pressurized gas to the keg forcing the beer out. When the beer tap handles on this system are pulled they open a valve. Because the beer is under pressure in the keg it is pushed out of the dispenser.

Pressurized taps result in fizzier beer because they use pressurized gas to push beer from the keg to the bar. During this process some of the gas is inevitably absorbed by the beer. Naturally, more pressure means more gas and more gas means more fizz. Too much gas results in beers that are all head and too little means the beer will seem flat or might not properly come out of the tap.

Tap handles were once simply objects of function; they became serious marketing tools for breweries. As such they needed to catch the customer's eye and clearly communicate which brewery and beer they dispensed.

Tall, ornate and sometimes garish tap handles are familiar objects in bars today. They are brightly colored and eye catching; sometimes shaped to represent another object that is associated with the beer.

These more fantastic handles tend to be exclusive to pressurized tap systems. Real or cask ale beer engine handles are generally more uniform. Although there are variations, the handles are usually long, straight and easy to grip. Tradition and practicality require that they remain unchanged; there is actual work involved in bringing the beer up from the cask as the operator has to apply some amount of pressure to the handle therefore wild or oddly shaped sculpture handles would be impractical. However beer clips are used to identify and market the beer available. These tend to be plain when compared to some of the handles but they effectively serve the same function. They are of different sizes and shapes, usually colorful and eye catching.