Encyclopedia Dubuque

"Encyclopedia Dubuque is the online authority for all things Dubuque, written by the people who know the city best.”

Marshall Cohen—researcher and producer, CNN

Affiliated with the Local History Network of the State Historical Society of Iowa, and the Iowa Museum Association.

BRICK MANUFACTURING: Difference between revisions

No edit summary |

No edit summary |

||

| (32 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

[[Image:brick.jpg|left|thumb|500px|A typical brick manufacturing operation in the 1800s.]] | |||

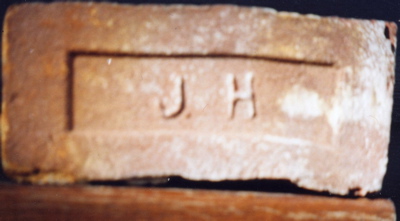

[[Image:brickyard.jpg|right|thumb|300px|Heim brickyard c.1900. Photo courtesy: Bob Reding]]BRICK MANUFACTURING. An announcement was made in November, 1855 that at least one brick-making machine might be brought to the city the following spring. The [[EXPRESS AND HERALD]] declared such an occurrence would be necessary if the city was to house its growing population. (1) | |||

In 1891 clay from the farm of [[STEWART, Robert W.|Robert W. STEWART]] was shipped to a brick manufacturer in Philadelphia. Its return in the form of high quality pavement brick indicated the beginning of a new industry for Dubuque. (2) In the late nineteenth century, most brick works were similar. Soak pits were used to prepare and mix clay with water. This was soaked overnight for softening so that it could be shaped into bricks using wooden forms. (3) | |||

In the early days, the drying process called "edging" required that the bricks be placed on their sides. Children earned ten cents an hour helping the turn the bricks. (4) | |||

Longer drying periods of up to three weeks occurred in "alleys." When the bricks were dry enough, they were placed in kilns to be burned--a process from which they got their red color. "Mobile kilns" were taken to the construction sites for brick making with cooks accompanying the workers on out-of-town jobs. (5) The kilning process took from two to three days and then varying times to cool. Bricks closest to the fire were called "maroon bricks." A dark red color, these bricks were used on outside walls. Bricks furthest away from the fire were called "soakers" because they absorbed water. These were used in the construction of inside brick walls. (6) | |||

Once technology began to take over, molding the bricks into the proper shapes became easier by using a soft-mud brick machine. The machine automatically shaped the pieces of clay into the form of bricks. A talented brick maker could produce about 4,000 bricks per day by hand. By the 1890s, some brick machines could produce up to 5,000 bricks per hour. | |||

Brick making in Dubuque declined as a major industry during the [[GREAT DEPRESSION]]. | |||

See: [[HEIM BRICK COMPANY]] | |||

--- | |||

Source: | |||

1. "The Prospects of Dubuque," ''Express & Herald'', November 27, 1855, p. 2 | |||

2. "Paving Brick in Dubuque," ''Dubuque Herald'', January 1, 1891, p. 4 | |||

3. Thran, Sally. "Foundation for Early Dubuque," ''Telegraph Herald'', July 16, 1961, (Dubuque News) p. 1 | |||

4. Ibid. | |||

5. Ibid. | |||

6. Thompson, Bob. '''Born on a Mountaintop'''. New York: Crown Trade Group, 2012, p. 46 | |||

7. "Caught on the Fly," ''The Daily Herald'', February 9, 1876, p. 4 | |||

8. "Changed His Base," The Daily Herald, December 1, 1878, p. 4 | |||

9. "Caught on the Fly," ''The Dubuque Herald'', May 2, 1885, p. 4 | |||

10. "Death of W. E. Bentley," ''The Herald'', September 5, 1891, p. 4 | |||

[[Image:imp940.jpg|left|thumb|150px|Photo courtesy: Bob Reding]] | |||

[[Image:imp941.jpg|right|thumb|150px|Photo courtesy: Bob Reding]] | |||

[[Image:MBC.jpg|left|thumb|150px|Photo courtesy: Bob Reding]] | |||

'''Historic Brick Manufacturers of Dubuque''' | |||

1859 | 1859 | ||

| Line 16: | Line 57: | ||

John Behrens Division near Lake | John Behrens Division near Lake | ||

Caleb Knapp head of Third | Caleb Knapp [[KNAPP BRICKYARD]] head of Third | ||

1868-1869 | 1868-1869 | ||

| Line 32: | Line 73: | ||

A. Knapp southwest corner of Julien Ave. and Nevada | A. Knapp southwest corner of Julien Ave. and Nevada | ||

Bernard J. O'Neill west side of Hill between Fifth and Pine | Bernard J. O'Neill west side of Hill between Fifth and Pine. In 1876 he purchased 1.5 acres once owned by Brown & Hedley for brick | ||

making giving him six acres "of the best material for brick making in the city." (7) In the winter, O'Neill became a grain buyer. (8) | |||

1873-1874 | 1873-1874 | ||

| Line 40: | Line 82: | ||

Hildebrand & Ham on Division | Hildebrand & Ham on Division | ||

August | August Roeber Eagle Point | ||

1874-1875 | 1874-1875 | ||

| Line 48: | Line 90: | ||

Platz & Dietrich Division | Platz & Dietrich Division | ||

[[ROEBER, August|August ROEBER]] north side of Lake east of 9th | |||

1875-1876 | 1875-1876 | ||

| Line 62: | Line 104: | ||

J. Platz Division | J. Platz Division | ||

A. | A. Roeber head of Lake | ||

1876 | 1876 | ||

| Line 73: | Line 115: | ||

O.C. Knapp near corner Dodge and Grandview | O.C. Knapp near corner Dodge and Grandview | ||

1885 | |||

Frank Chesterman (location unknown) employed up to eight men. (9) | |||

1886-1887 | 1886-1887 | ||

| Line 82: | Line 128: | ||

1889 | 1889 | ||

William Bentley 204 Delhi | William Bentley 204 Delhi. Operated this brickyard for two years. (10) | ||

1899 | 1899 | ||

| Line 101: | Line 147: | ||

John Heim Broadway Extension | John Heim Broadway Extension | ||

[[Category: Industry]] | |||

Latest revision as of 17:15, 23 February 2023

BRICK MANUFACTURING. An announcement was made in November, 1855 that at least one brick-making machine might be brought to the city the following spring. The EXPRESS AND HERALD declared such an occurrence would be necessary if the city was to house its growing population. (1)

In 1891 clay from the farm of Robert W. STEWART was shipped to a brick manufacturer in Philadelphia. Its return in the form of high quality pavement brick indicated the beginning of a new industry for Dubuque. (2) In the late nineteenth century, most brick works were similar. Soak pits were used to prepare and mix clay with water. This was soaked overnight for softening so that it could be shaped into bricks using wooden forms. (3)

In the early days, the drying process called "edging" required that the bricks be placed on their sides. Children earned ten cents an hour helping the turn the bricks. (4)

Longer drying periods of up to three weeks occurred in "alleys." When the bricks were dry enough, they were placed in kilns to be burned--a process from which they got their red color. "Mobile kilns" were taken to the construction sites for brick making with cooks accompanying the workers on out-of-town jobs. (5) The kilning process took from two to three days and then varying times to cool. Bricks closest to the fire were called "maroon bricks." A dark red color, these bricks were used on outside walls. Bricks furthest away from the fire were called "soakers" because they absorbed water. These were used in the construction of inside brick walls. (6)

Once technology began to take over, molding the bricks into the proper shapes became easier by using a soft-mud brick machine. The machine automatically shaped the pieces of clay into the form of bricks. A talented brick maker could produce about 4,000 bricks per day by hand. By the 1890s, some brick machines could produce up to 5,000 bricks per hour.

Brick making in Dubuque declined as a major industry during the GREAT DEPRESSION.

See: HEIM BRICK COMPANY

---

Source:

1. "The Prospects of Dubuque," Express & Herald, November 27, 1855, p. 2

2. "Paving Brick in Dubuque," Dubuque Herald, January 1, 1891, p. 4

3. Thran, Sally. "Foundation for Early Dubuque," Telegraph Herald, July 16, 1961, (Dubuque News) p. 1

4. Ibid.

5. Ibid.

6. Thompson, Bob. Born on a Mountaintop. New York: Crown Trade Group, 2012, p. 46

7. "Caught on the Fly," The Daily Herald, February 9, 1876, p. 4

8. "Changed His Base," The Daily Herald, December 1, 1878, p. 4

9. "Caught on the Fly," The Dubuque Herald, May 2, 1885, p. 4

10. "Death of W. E. Bentley," The Herald, September 5, 1891, p. 4

Historic Brick Manufacturers of Dubuque

1859

A. Graham corner of Hill and 5th Street

P.S. Wells corner of Hill and 5th Street

1867

John Behrens Division near Lake

Caleb Knapp KNAPP BRICKYARD head of Third

1868-1869

John Blake Mineral near Seventeenth

Anton Heeb south side of Eagle Point Ave. near Couler Ave.

Hughes & Hutton head of Third

Mrs. Harriet Wells north east corner of Fifth and Hill

1870-1871

A. Knapp southwest corner of Julien Ave. and Nevada

Bernard J. O'Neill west side of Hill between Fifth and Pine. In 1876 he purchased 1.5 acres once owned by Brown & Hedley for brick making giving him six acres "of the best material for brick making in the city." (7) In the winter, O'Neill became a grain buyer. (8)

1873-1874

John Heim Couler Ave. and 29th

Hildebrand & Ham on Division

August Roeber Eagle Point

1874-1875

T.B. Ham 740 High

Platz & Dietrich Division

August ROEBER north side of Lake east of 9th

1875-1876

Hutton & Curry 495 West 5th

A.J. Knapp West end West 3rd

C. Knapp corner of Grandview and Dodge

C.H. Mattox corner of Hill and 5th

J. Platz Division

A. Roeber head of Lake

1876

Graham corner of Hill and 5th

1878-1879

August Roeber west side Lake between 6th and 7th

O.C. Knapp near corner Dodge and Grandview

1885

Frank Chesterman (location unknown) employed up to eight men. (9)

1886-1887

John Dietrich 93 Lincoln

D. Maggenburg east side of Broadway north of Diagonal

1889

William Bentley 204 Delhi. Operated this brickyard for two years. (10)

1899

Dietrich Bros 1203 Lincoln

Eagle Point Lime Works Lime near Lincoln

Albert Gasser Grandview and Fremont, 307 Grandview

Mrs. Agatha Heim 3403 Couler Ave.

1909

Dietrich & Beutin yards on hill west of Lincoln and Ann

1911

John Heim Broadway Extension